- BIM Business Observations

- Posts

- The construction sector: deeply innovative, but you simply can’t compare it

The construction sector: deeply innovative, but you simply can’t compare it

Construction innovates differently

When people think about innovation, their minds usually jump to shiny electric cars, rockets shooting into space, or sleek smartphones that somehow get thinner and more powerful every year.

These sectors — automotive, aerospace, tech — are built around big, dramatic leaps. A few major players set the pace, make the decisions, and roll out new technologies across the entire world in one go.

But what if I told you that the construction sector is just as innovative — maybe even more so?

The difference? Construction innovates in a way that’s quieter, more fragmented, and deeply rooted in real-world practice. And that’s exactly why you simply can’t compare it to other industries.

Every building is a prototype

Unlike cars or phones that come off the line in identical batches of millions, every new building is essentially a one-off prototype.

Each project is a fresh puzzle with its own shape, site conditions, design ambitions, and technical challenges. To make it work, you need a team of highly specialized players: architects, engineers, façade designers, contractors, window and insulation suppliers, and dozens of niche trades.

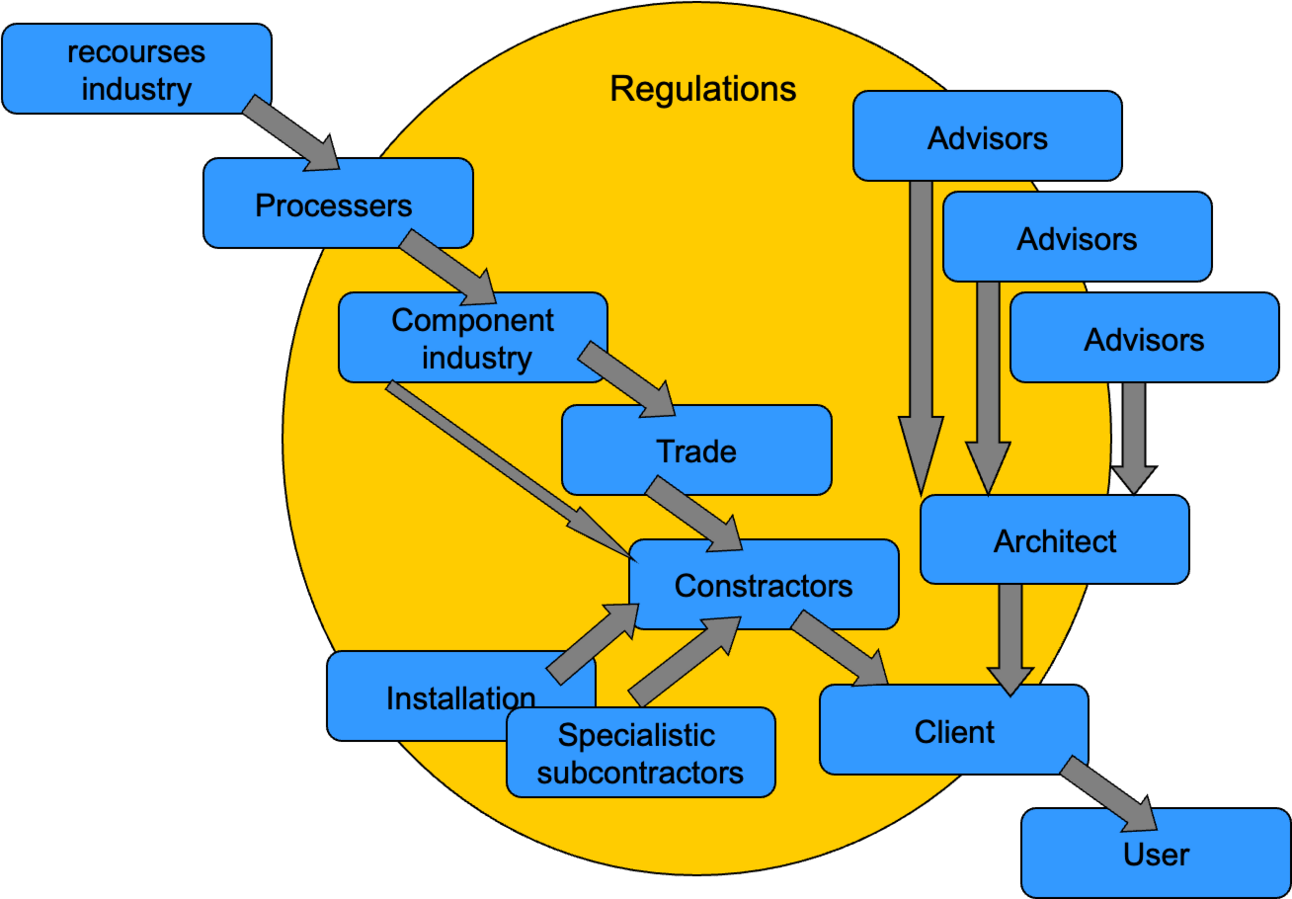

Source: building systems innovation group TNO

This so-called “fragmentation” isn’t a weakness. In fact, it’s the sector’s biggest strength. It creates a living network of expertise, where each specialist contributes deep knowledge and unique craftsmanship.

A powerful example: prefabricated façades

Let’s look at one example that shows how construction really innovates: prefabricated façade systems.

Traditionally, façades are built brick by brick on site. Windows are installed one at a time. Insulation is layered in by hand. And the entire building sits behind scaffolding for months, fully exposed to weather and delays.

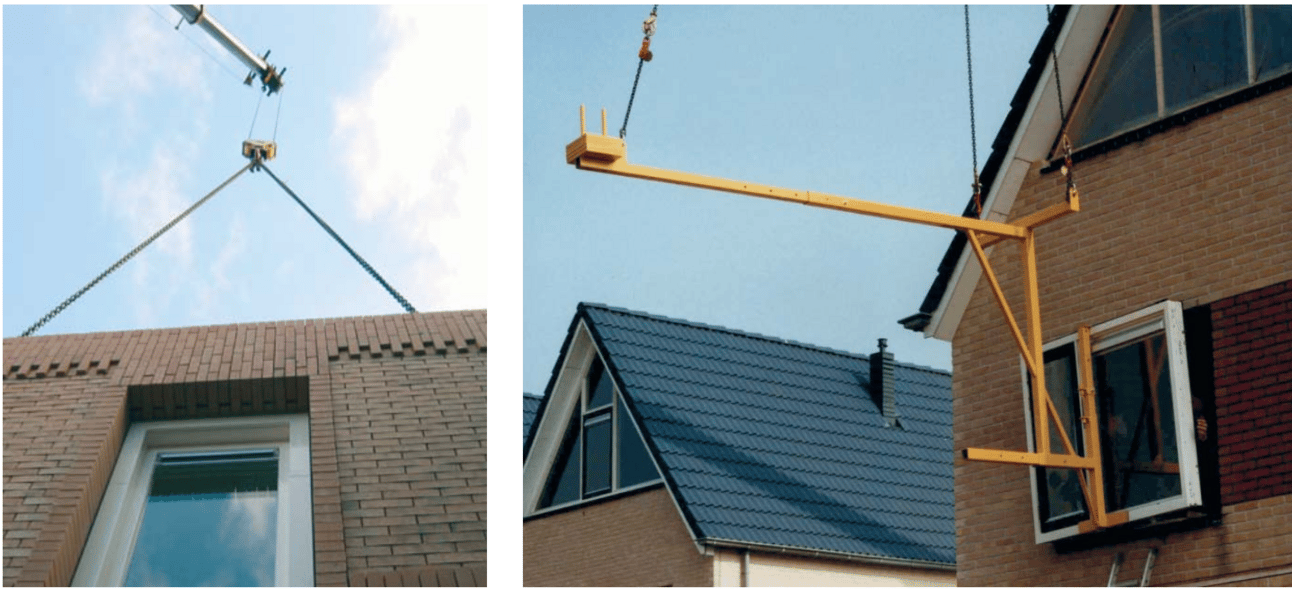

source: cross border innovations in the construction sector

Prefabricated façades flip this model upside down. Entire façade panels are built in a factory, complete with brickwork, insulation, pre-painted and glazed windows, and detailed finishing. These panels arrive on site ready to install. With a crane, they’re placed in hours instead of weeks. Suddenly, a building can be closed off and weather-tight in just a few days.

It sounds simple. In reality? It changes everything.

To make prefabricated façades possible, every specialist in the chain has to rethink their role.

Architects need to design for factory constraints and modular panel sizes, which challenges their traditional freedom. Engineers have to calculate new load paths and connection details. Window and insulation manufacturers must coordinate closely to integrate their systems before anything reaches the site.

Contractors need to manage new logistics — no more daily brick deliveries, but massive, just-in-time façade panels that must fit perfectly. On-site crews have to learn entirely new skills to handle and align these large elements safely and precisely.

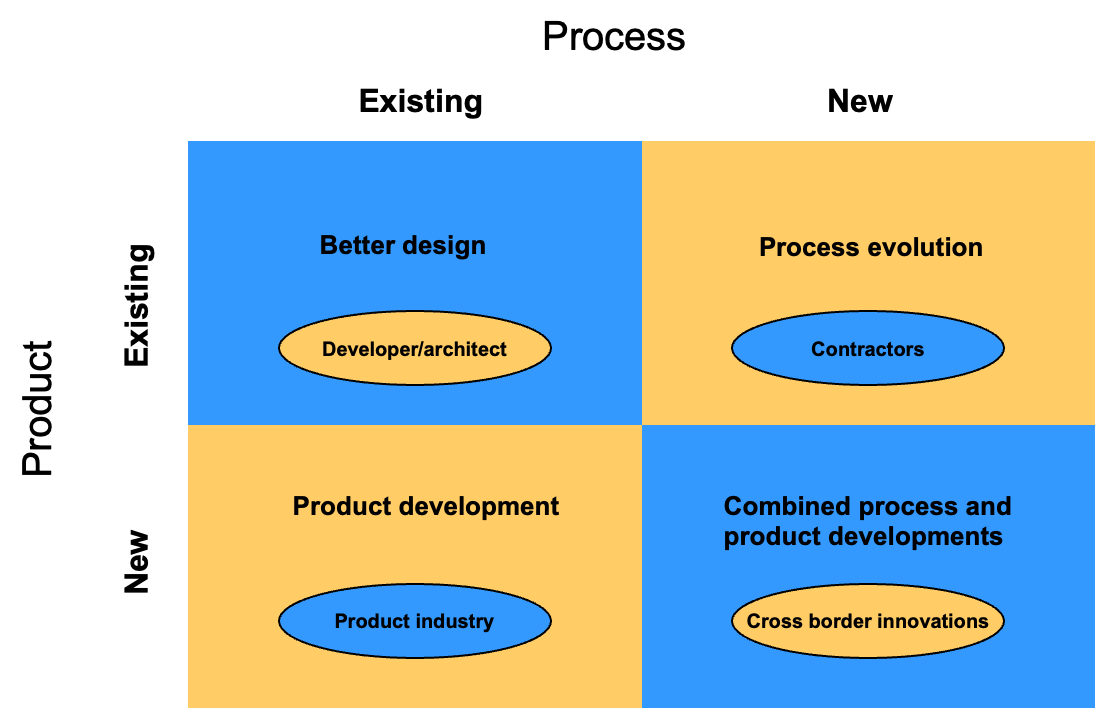

source: building systems innovation group TNO

And this is just the beginning.

No two projects are the same

The biggest challenge? Every project is different.

One building might need large corner windows, another might have curved lines or intricate brick patterns. A third might demand ultra-high energy performance or special acoustic treatments.

Even with prefabrication, customization is essential. Standardization can only go so far. There’s no freezing a design and repeating it endlessly. Every project is a fresh test, a new learning curve, a new story.

Why construction innovation is so different

In industries like automotive or tech, a central headquarters makes a decision, and the entire supply chain falls in line.

In construction, there’s no central command. There’s no one big player forcing everyone to switch to a new system overnight. Every innovation has to win over dozens of independent players — each with their own priorities, risks, and deep-rooted practices.

Change only happens when it proves itself in practice and when enough people trust it to work, together.

Progress through collective evolution

Prefabricated façades show how construction innovates: not through sudden, top-down revolutions, but through careful, collective evolution.

They deliver higher quality by moving work into controlled factory conditions. They speed up timelines and reduce on-site risks. They help reduce waste and avoid delays.

But none of this happens overnight. It demands patience, coordination, shared risk, and trust among all the parties involved.

You simply can’t compare

This is exactly why you can’t compare construction to automotive, aerospace, or tech.

In construction, progress depends on human relationships, shared expertise, and practical problem-solving — not on a single sweeping decision from above.

Construction is deeply human. It relies on skilled people who understand the smallest details, who adapt to muddy sites and unexpected surprises.

Here, progress doesn’t come from big product launches, but from countless small, practical steps, each one tested and refined in the real world.

Innovation on its own terms

In the end, construction is deeply innovative — but always on its own terms. Instead of mass-produced revolutions, it delivers tailored solutions. Instead of headline-grabbing breakthroughs, it builds steady, shared improvements that make every building safer, faster, and more beautiful.

That is what makes construction so special. It’s a sector full of quiet, powerful innovations — impossible to compare, and all the stronger for it.